Exploring the Types of Multi-Head Scales in Packaging

Type of multi-head scale

Multi-head scales play a crucial role in modern packaging operations, offering high-speed and precise weighing solutions for a variety of products across industries. These scales utilize advanced technology to ensure accurate portioning and packaging, enhancing efficiency and productivity on production lines.

1. Linear Multi-Head Scales:

Linear multi-head scales consist of multiple linear weighers arranged in parallel, allowing simultaneous weighing and portioning of products. Each linear weigher operates independently, depositing portions of the product into the packaging machine's funnel or conveyor. Linear multi-head scales are ideal for packaging applications requiring high-speed weighing of uniform products such as snacks, candies, nuts, and frozen foods.

2. Rotary Multi-Head Scales:

Rotary multi-head scales feature a rotating distribution system that evenly distributes products to individual weighing hoppers. As the product moves along the rotary feeder, it is discharged into the weighing hoppers, where precise measurements are taken. Rotary multi-head scales are suitable for handling delicate or fragile products that may be prone to damage during handling, such as fresh produce, meat, poultry, and seafood.

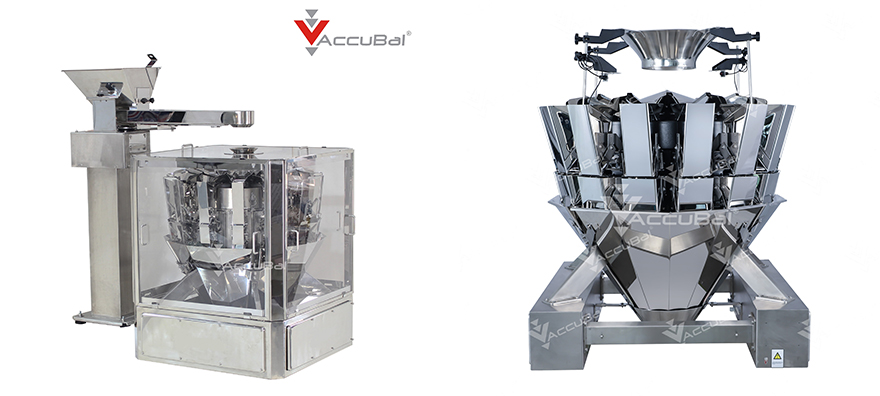

3. Combination Multi-Head Scales:

Combination multi-head scales integrate multiple linear and rotary weighing heads within a single machine, offering versatility and flexibility in packaging operations. These scales combine the high-speed capabilities of linear scales with the gentle handling of rotary scales, making them suitable for a wide range of products with varying shapes, sizes, and weights. Combination multi-head scales are commonly used in food processing, pharmaceuticals, and consumer goods industries.

Additional reading:Top 10 Tips for Choosing Pallet Wrapping Equipment?

What are the best practices for wrapping pallets?

Ultimate Guide to Arm Wrapping Machines: FAQs, Uses & Benefits

Revolutionize Your Shipping Process with a Pallet Wrapper

Maximizing Efficiency with Pallet Stretch Machine Tips

Get Your Car Looking Sharp with Top Auto Wrapping Equipment!

Revamping Industrial Wrapping Machines for Sustainable Packaging?

4. Modular Multi-Head Scales:

Modular multi-head scales consist of individual weighing modules that can be configured and customized according to specific production requirements. Each weighing module operates independently, allowing for seamless integration with existing packaging machinery and production lines. Modular multi-head scales offer scalability and adaptability, making them ideal for small to medium-sized businesses with evolving needs and production demands.

5. Volumetric Multi-Head Scales:

Volumetric multi-head scales utilize advanced technology to measure product volume rather than weight, making them suitable for non-uniform or irregularly shaped products. These scales employ sensors and imaging systems to calculate the volume of each product and dispense precise portions into packaging containers. Volumetric multi-head scales are commonly used in industries such as pharmaceuticals, chemicals, and hardware, where accurate volumetric measurements are critical for product consistency and quality.

Conclusion:

Multi-head scales are essential components of modern packaging operations, offering efficient, accurate, and high-speed weighing solutions for a wide range of products. Whether utilizing linear, rotary, combination, modular, or volumetric configurations, multi-head scales play a crucial role in ensuring product consistency, quality, and cost-effectiveness in packaging applications across industries. By understanding the different types of multi-head scales and their respective features, manufacturers and packaging professionals can make informed decisions when selecting the most suitable weighing solution for their specific production needs and requirements.

Revolutionize Your Packaging Process with High-Speed Automation

How do I select a Stretch Wrap Machine with Scales?

How Palet Machine Can Increase Production Efficiency.

Top Deals: Pallet Wrapper Machine for Sale

How much does an automatic pallet wrapper cost?

Revolutionizing Packaging: Is Auto Semi Stretch Wrapper?

How to Choose Cloud-Based Pallet Wrapping Solutions? A Comprehensive Guide

Comments

0