Differences Between 304 and 316 Stainless Steel

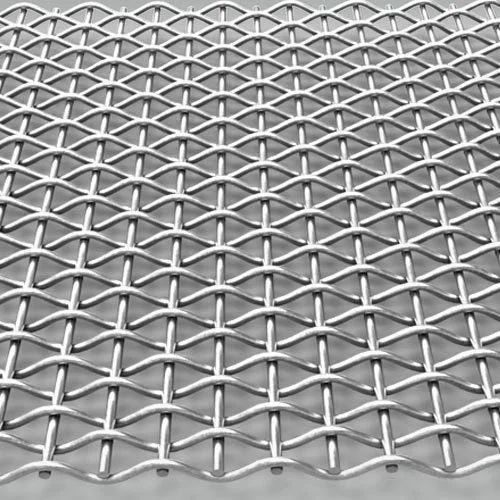

All stainless steels are not manufactured in the same way. There are grades of stainless steel. The "grade" of stainless steel refers to its quality, durability and temperature resistance. Figuring out what stainless steel you need is an important step in your next project involving stainless steel mesh. Type 304 and Type 316 stainless steel wire mesh are the two most commonly used types, but it's important to understand the differences between the two.

Known as A2 stainless steel, 304 stainless steel is the most common of the stainless steel family. The most common form of 304 stainless steel is 18-8 or 18/8 stainless steel, which contains 18% chromium and 8% nickel.

304 stainless steel mesh can withstand corrosion from most oxidising acids. This durability makes this grade of stainless steel easy to sterilise, an ideal advantage for kitchen and food applications. 304 Stainless Steel is also common in architectural, decorative and site furnishings.

304 stainless steel is an austenitic stainless steel, which means it is a solid solution of carbon in non-magnetic iron. This means that this grade is non-magnetic and has poor thermal and electrical conductivity. While it has excellent ductility and can be moulded into desired shapes, it also has higher corrosion resistance compared to ordinary steel. 304 is susceptible to corrosion from chloride solutions or salt-laden environments such as the coast.

316 Stainless Steel, also known as Marine Grade Stainless Steel or A4 Stainless Steel, is known for its enhanced corrosion resistance as well as its ability to excel in salt water and marine applications. While it has the same physical properties as 304 and similar utility functions, the major difference is the addition of molybdenum, which is typically 2-3% by composition (although some speciality 300 series stainless steels can contain up to 7-8% molybdenum).

The increased nickel content and the addition of molybdenum make 316 stainless steel wire mesh somewhat more expensive than 304 grades, but it offers higher corrosion resistance than 304 grades, particularly against chlorides and chlorinated solutions. 316 stainless steel is commonly used in chemical processes and high-salt environments where chloride resistance is required, and is also widely used in the manufacture of medical and surgical equipment due to its non-reactive properties.

Learn the difference between 304 and 316 stainless steel to help you make your purchasing decision.

Rongtai offers a full range of 304 and 316 stainless steel as well as other grades of wire mesh. The benefits of stainless steel also come with longevity and proper care, as low maintenance requirements and long service life ensure that architectural and mechanical integrity will not be a problem for years to come.

If you plan to use stainless steel in a saltwater environment, 316 is the right alloy. If you're looking for a durable alloy and don't need superior corrosion resistance, 304 stainless steel can work perfectly. To learn more about what each stainless steel can do for you and to find the best product for your application, please contact us. We'll be happy to assist you in determining whether 304 or 316 stainless steel is right for your metal mesh project.

Comments

0