CHEMICAL INJECTION PUMPS

What are Chemical Injection Pumps?

Chemical injection pumps are designed to improve well production, pipeline flow, and reduce corrosion. They operate under specific chemical and fluid requirements depending on the temperature and pressure with which the injection pump will be working at. Ultimately, chemical injection pumps deliver specific chemicals to the production system at determined rates. These procedures are required for the safe application of chemicals and for oilfield systems to work efficiently. Chemical Injection Pumps are common systems within the Canadian oil and gas industry. Some of the chemicals used include solvents, de-salting agents, corrosion inhibitors, biocides, clarifiers, scale inhibitors, hydrate inhibitors, oxygen scavengers, surfactants, and more. Sometimes methanol is used to reduce freezing which causes pipelines to clog. This can be a complex subject, but it is important to understand the different applications, limitations, and conditions that contribute to the efficiency of these systems and their overall performance.

Uses or Applications of Chemical Injection Pumps

Agriculture

Chemical manufacturing and processing.

Oil & gas production

Cryogenics

Automotive

Pulp and paper manufacturing

Food processing

Semiconductors

About suncenter manufacturing

Suncenter is a world-leading manufacturer of fluid pressure control and testing equipment, dedicated to provide more efficient and safer fluid pressure control device to worldwide clients. The company has obtained CE certification, SGS certification and products are exported to more than 100 countries around the world, and it has won good reputation, and has become a leader in the fluid pressurization field.

Pump Types

There are different types of pumps used as chemical injection pumps. Generally, chemical injection pumps are divided in two categories, gas driven or electric driven.

Gas driven pumps are also called pneumatic chemical injection pump and are classified as either piston type or diaphragm type. Both operate in the same way but vary in the mechanism that drives the chemicals.

Pneumatic or gas driven injection pumps

Positive displacement pumps and diaphragm chemical pump: Operates from gas pressure and has a single head. The amount of gas being injected is directly related to the stroke length.

Additional reading:Should businesses invest in automated luggage machines at airports?

Unlocking the Secrets: Butter Extraction Machine Explained

What are the advantages of extrusion in food processing?

Is the L Bar Pof Film Shrink Wrapping Machine the Best Investment for Your Business Needs?

How do you get oil out of nuts?

Maximizing Efficiency with Palletising Machine Automation

7 Must-Have Cold Press Machine Recipes

Metering type pumps can be used for chemical injections as well as water. They can work at high pressures and allow for continuous flow rates to be averaged over time. The best way to avoid leaks is by implementing diaphragm pumps for metering. Diaphragm pumps are better in the sense that they are accurate with no leaks, resulting in a more efficient pump with a longer product life.

Electric Chemical Injection Pumps: AC or DC

The designs of electrical chemical injection pumps are similar because they are driven by a piston, but the motor and power are different. Piston-driven injection pumps contribute to operations by preventing the system from venting gas. Direct Current electric chemical injection pumps came to be in places where AC is not available, often in remote areas. They are a great alternative to pneumatic chemical injection pumps in terms of cost and environment.

Plainsman Manufacturing Chemical Injection Pumps

All pumps are designed and produced with chemically resistant materials due to the extreme conditions they can be put under. While the operation may vary, some pumps are operated mechanically while others operate by an electric motor, or compressed field gas or air. The rates at which chemicals can enter varies depending on the volume of chemicals and type of pump. There are pumps that allow for two chemicals to be pumped simultaneously. Visit our website and browse through our selection of Chemical Injection Pumps and Accessories.

Feel free to give us a call or contact us with any questions, comments, or concerns, our customer service experts will be glad to assist you.

The following list quickly names the key advantages of implementing chemical injection pumps:

Very accurate

Simple in design and relatively easy to install, adjust or repair

Operates under high pressures

Long pump life

Increase work safety

Reduce green house gas emissions, and odors

Efficient systems will reduce fire hazards as well

Chemical Injection Pumps Maintenance:

As any other process in oil and gas production, high levels of inspection and monitoring are required. To efficiently run and maintain chemical injection systems, operators should keep track and record all activity. The most important details to keep records of are the number of chemical injection pumps used, data for the different types of chemical injection pumps, fuel and gas consumption levels, any change or upgrade performed, and MSDS data sheets for all chemicals being used.

Optimization can be achieved by increasing the stroke and diameter of the pump to decrease and minimize frequency. Also, pump injection rate and injection pressure should be carefully measured to minimize the use of fuels. Remember chemical consumption rates will vary according to the different types of pumps.

Revolutionary Pet Treats Forming Machine: A Gamechanger?

How to Enhance Product Packaging Efficiency with L Bar Pof Film Shrink Wrapping Machine?

Revolutionizing Beauty Industry: Castor Oil Machines?

Discover the Best Deals on Food Extruder Machine Price Now!

Mastering Efficiency: Automatic Pallet Stretch Wrapping Machine

What is the Difference Between Articulating Lift and Boom Lift?

What Is the Difference Between a Forklift and a Fork Truck?

Related Articles

-

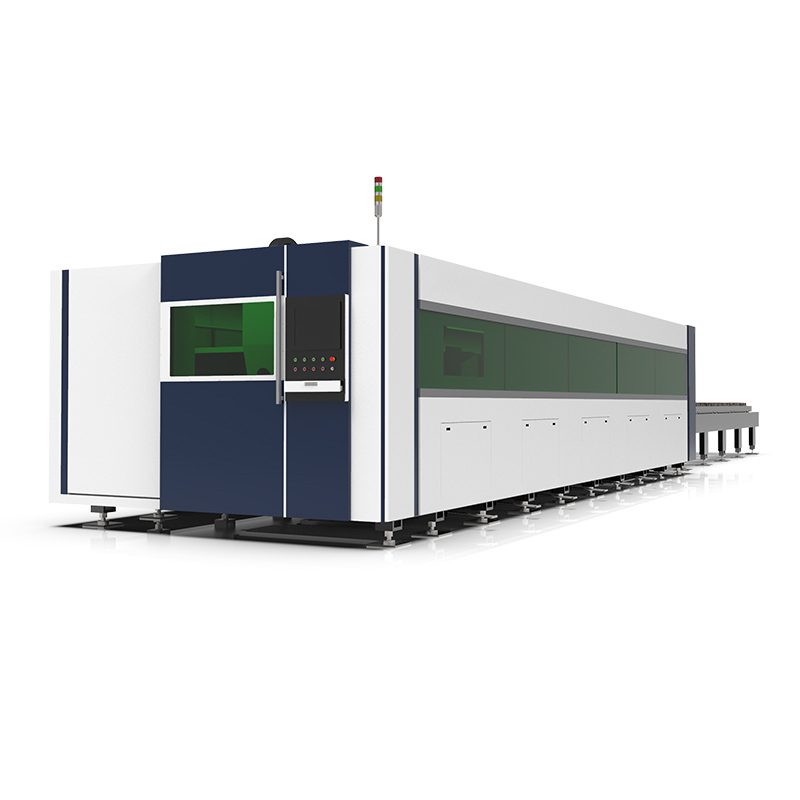

What are the daily maintenance of fiber laser cutting machines?

149

0

0

-

Understanding the Operation of a Pneumatic Chemical Injection Pump

-

Powering Progress: Advantages and Applications of Slip Ring Induction Motors

-

Understanding the Chill: Exploring the Difference Between AC and Chiller Systems

-

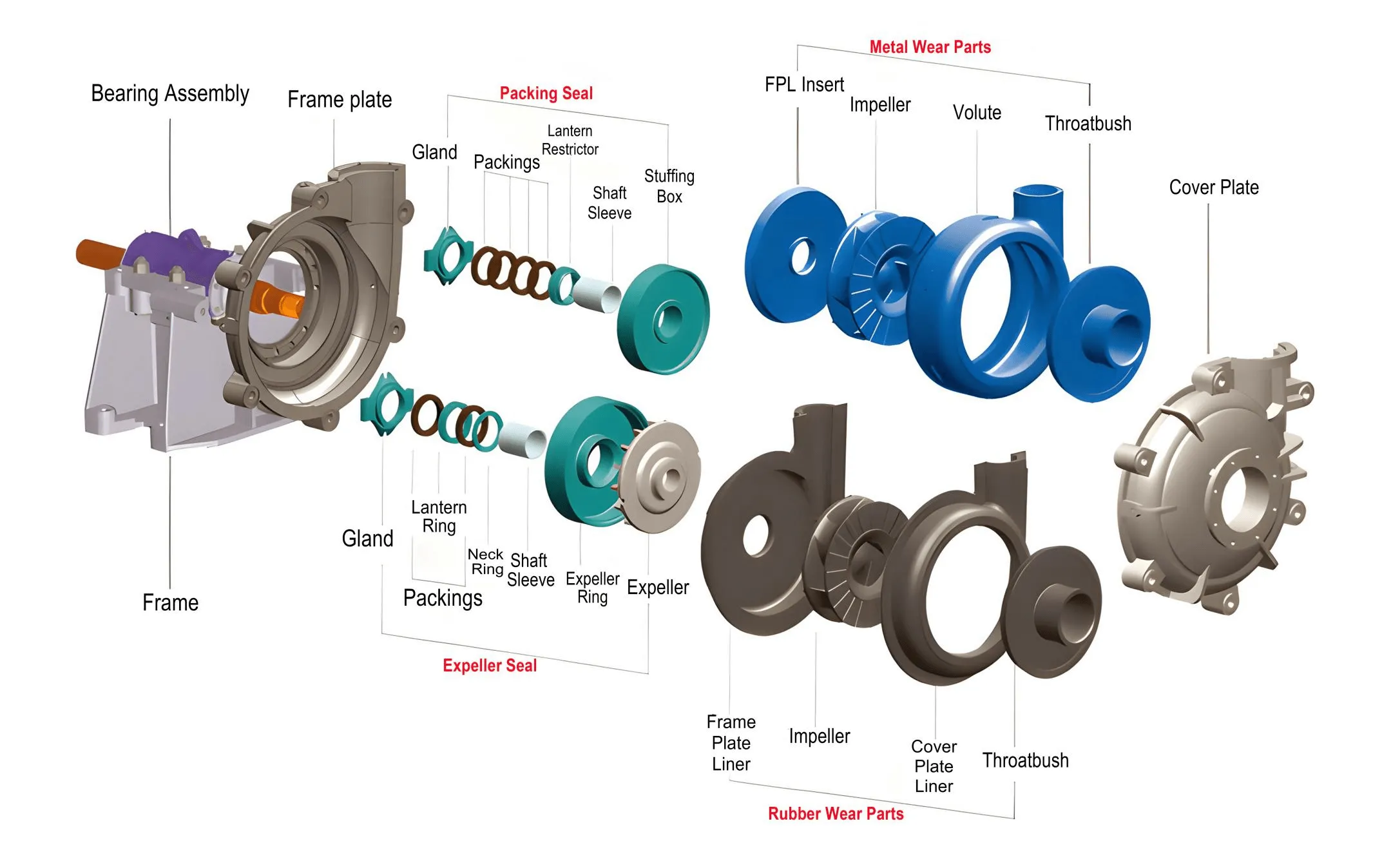

Prolonging Pump Life: When and How to Replace Slurry Pump Parts

153

0

0

Comments

0